Energy Machinery, Inc.

10 Reservoir Park Drive

Rockland, MA 02370

Toll Free: 1-800-643-4330

10 Reservoir Park Drive

Rockland, MA 02370

Toll Free: 1-800-643-4330

| Items |

HTA100 100 Standard Cubic Feet per Minute (scfm) High Temperature Afterfilter List Price QUOTE

|

HTA200 200 Standard Cubic Feet per Minute (scfm) High Temperature Afterfilter List Price QUOTE

|

HTA400 400 Standard Cubic Feet per Minute (scfm) High Temperature Afterfilter List Price QUOTE

|

HTA600 600 Standard Cubic Feet per Minute (scfm) High Temperature Afterfilter List Price QUOTE

|

HTA1200 1200 Standard Cubic Feet per Minute (scfm) High Temperature Afterfilter List Price QUOTE

|

|||||

| Description |

N/A

Filtration for High Temperature Applications Hankison®'s HTA Series high temperature afterfilters are designed to capture large amounts of desiccant fines. Housing and element construction are ideally suited for installation downstream of heated desiccant air dryers. |

|||||||||

| Maximum Flow at 100 psig (6.7 bar) | N/A 100 scfm170 nm³/h | N/A 200 scfm340 nm³/h | N/A 400 scfm680 nm³/h | N/A 600 scfm1019 nm³/h | N/A 1200 scfm2039 nm³/h | |||||

| Housing Type | N/A Bowl Head | N/A Bowl Head | N/A Pressure Vessel | N/A Pressure Vessel | N/A Pressure Vessel | |||||

| Maximum Working Pressure at 450 ºF (232 ºC)1 | N/A 250 psig17.6 bar | N/A 250 psig17.6 bar | N/A 165 psig11.6 bar | N/A 165 psig11.6 bar | N/A 165 psig11.6 bar | |||||

| Inlet Connection Size | N/A 1 in | N/A 1 in | N/A 3 in | N/A 3 in | N/A 3 in | |||||

| Inlet Connection Type | N/A NPT | |||||||||

| Outlet Connection Type | N/A NPT | |||||||||

| Outlet Connection Size | N/A 1 in | N/A 1 in | N/A 3 in | N/A 3 in | N/A 3 in | |||||

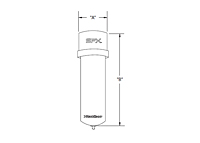

| Width A | N/A 4.25 in | N/A 4.25 in | N/A 10.25 in | N/A 10.25 in | N/A 16.00 in | |||||

| Height B | N/A 14.31 in | N/A 23.81 in | N/A 39.56 in | N/A 39.56 in | N/A 41.44 in | |||||

| Weight | N/A 13 lb | N/A 19 lb | N/A 95 lb | N/A 95 lb | N/A 159 lb | |||||

| Replacement Cartridge Number | N/A 0740-1 | N/A 0740-2 | N/A 0740-3 | N/A 0740-4 | N/A 0740-4 | |||||

| Quantity Required | N/A 1 | N/A 1 | N/A 1 | N/A 1 | N/A 2 | |||||

| Series | N/A HTA | |||||||||

| Brands | N/A Hankison® SPX® | |||||||||

| Maximum Temperature | N/A 450 ºF232 ºC | |||||||||

| Stage 1: Gravitational Setting | N/A Compressed air leaves a desiccant dryer containing dust concentrations typically in the range of up to 0.05 ppm by weight in heatless type dryers and up to 5 ppm by weight in heated type dryers. Particle size ranges from 200 microns to about 1 micron. This desiccant laden compressed air enters the filter housing where a reduction in air velocity and a sharp change of direction cause particles in the range of 200 to 20 microns to drop to the bottom of the housing. | |||||||||

| Stage 2: Surface Filtration |

N/A

The air stream then enters the outside of the filter cartridge and flows through a layer of glass fabric cloth. Small diameter fibers, which form a web in the openings between thread strands, cause a dust layer to form as dust bridges the pores. Dust continues to collect on the outside of the cloth as separate loose particles. The voids between these particles form pores and flow-passages and become an efficient filter in itself. As the dust bed continues to thicken it reaches a point where outer layers of dust shed off the cartridge into the bottom of the housing. |

|||||||||

| Stage 3: In-Depth Filtration |

N/A

Air next travels through a multi-layer graded in-depth filter media where all remaining fines one micron and larger are captured. A final wrap of glass fabric cloth prevents fiber migration. |

|||||||||

| Additional Information |

N/A

|

|||||||||

| Note | N/A | N/A | N/A | N/A | N/A Model HTA1200 and larger are ASME code constructed and stamped. | |||||

|

||||||||||